Rebuilding the air end is one of the most effective ways to extend the life of your rotary screw air compressor. Whether it’s worth the investment depends on your compressor’s size, condition, and operational needs. This guide covers everything you need to know about how the air end works, signs of failure, causes of damage, and how to extend its lifespan.

What Is an Air End?

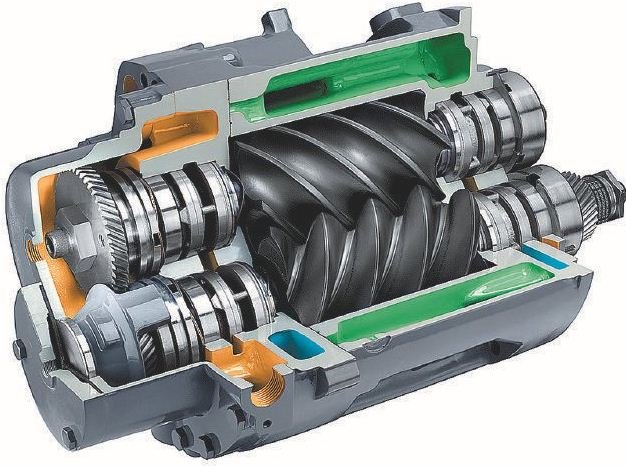

The air end is the heart of a rotary screw compressor — it’s where atmospheric air is compressed to the required pressure for your application. In rotary screw compressors, the air end includes the twin intermeshing rotors and the housing that forms the compression chamber. Precise alignment and tight tolerances are essential for efficient performance.

How the Air End Works in Rotary Screw Compressors:

Inside the air end, two rotors spin in opposite directions. As they turn, they trap air between their lobes and the casing. This trapped air is progressively compressed as it moves along the length of the rotors, reducing volume and increasing pressure.

Key Components of the Air End

- Rotors: Male and female rotors (or screws) interlock to compress air.

- Housing: Encloses the rotors and forms the compression chamber.

- Bearings: Support high-speed rotor movement with minimal friction.

- Lubrication System: Oil cools, lubricates, and seals during compression (in oil-injected compressors).

- Seals: Prevent leakage of compressed air and oil.

- Inlet & Outlet Valves: Control airflow into and out of the air end.

Do All Compressors Have an Air End?

All compressors have a compression mechanism, but the term “air end” is specific to rotary compressors like screw, scroll, or vane types. Reciprocating compressors use cylinders, and centrifugal units use impellers instead of what’s referred to as an air end.

Signs of Air End Failure

Air ends are durable, but wear over time. Watch for these common signs:

- Reduced CFM Output: Worn rotors or seals reduce efficiency.

- Higher Energy Use: Increased amperage may indicate internal wear.

- Unusual Noise or Vibration: Could signal misalignment, bad bearings, or rotor damage.

- Rising Temperatures: May suggest lubrication or cooling issues.

- Oil Loss or Leaks: Often caused by seal failure or cracks.

- Metal in Oil: A major red flag indicating internal component wear.

- Pressure Drops: Can result from worn rotors or compromised seals.

What Causes Air End Failure?

Several factors can accelerate wear and lead to premature air end failure:

- Inadequate Lubrication: Low or poor-quality oil increases friction and heat.

- Contamination: Dust and debris can damage rotors and bearings.

- Overheating: Can degrade oil and damage seals.

- Poor Maintenance: Skipping oil changes or filter replacements shortens lifespan.

- Running Outside Design Specs: Overloading pressure or temperature limits strains the air end.

- Misalignment or Imbalance: Causes excessive vibration and rotor wear.

How Long Does an Air End Last?

Lifespan varies by compressor type, usage, and maintenance. Typical ranges include:

- Oil-lubricated rotary screw compressors: ~80,000 hours (can be more with excellent maintenance).

- Oil-free rotary screw compressors: ~50,000 hours.

Air End Rebuilds: What to Expect

Rebuilding an air end can add 40,000 to 60,000 more hours of operation, depending on build quality and maintenance. While rebuilt units don’t match the lifespan of brand-new ones, they’re a cost-effective option when the rest of the compressor is still in good condition.

Note: Rebuilding only addresses the air end. Other systems—motor, cooling, controls—also impact overall compressor life.

Extending Air End Life: Best Practices

You can significantly extend the air end’s lifespan with proper care:

- Follow a Maintenance Schedule: Regular oil changes and inspections are essential.

- Use the Right Lubricant: Manufacturer-recommended oil ensures proper cooling and sealing.

- Keep Filters Clean: Prevent dust and debris from entering the system.

- Monitor Temperatures: Maintain proper cooling to avoid overheating.

- Operate Within Limits: Don’t exceed rated pressure, temperature, or duty cycle.

- Inspect Regularly: Catching early signs of wear can prevent catastrophic failure.

- Ensure Proper Installation: Alignment and startup procedures matter.

The air end is a vital component of your rotary screw air compressor — and maintaining it is essential for reliable, efficient performance. Whether you’re considering a rebuild or planning preventive maintenance, understanding the air end helps you make smart decisions that protect your investment and avoid costly downtime.

Ready to upgrade your compressed air system?

Contact No. : +91 9601415434

Email ID: info@loitha.com

website: https://loitha.com/

Facebook: LothAir/

Instagram:/loitha_Air/

Youtube: @LOITHAAir