High Pressure Screw Air Compressor

Introduction to High Pressure Screw Air Compressor

The High Pressure Screw Air Compressor is a vital part of modern compressed air systems, designed to deliver consistent, energy- high efficiency compressed air for a wide range of industrial processes. Unlike traditional reciprocating air compressors, the high-pressure screw air compressor ensures continuous operation, low noise levels, and minimal maintenance.

As a leading compressor manufacturer from Rajkot, Loitha has been powering industrial operations with advanced air compression technology. Our range of air compressors — from oil-free compressors to stage screw air compressors — is engineered to deliver clean, reliable, and heavy-duty industrial performance.

Features of Loitha

Higher Pressure Levels

Consistent pressurized air supply up to 16 bar and beyond.

Free Air Delivery (FAD)

Accurate cubic feet per minute (CFM) measurement ensures precise air output.

Heavy-Duty Air End

Robust air end designed for longer compressor life in tough industrial environments.

Energy-Efficient Design

Reduced energy consumption with advanced screw technology and variable-speed options.

Clean Compressed Air

Multi-stage air treatment for oil-free compressors to ensure contamination-free supply.

Low Noise Levels

Engineered for continuous industrial use with quiet operations.

Applications of Direct Drive screw Air Compressors

The High Pressure Screw Air Compressor is widely used across:

- Manufacturing Applications –consistent pressure for heavy machinery.

- Textile Industry – air compressors are essential for weaving, spinning, and finishing.

- Ceramic industry – stable compressed air for molding and drying.

- Food & beverage packaging – clean, oil-free compressors ensure contamination-free processes.

- Automotive applications – dependable air for painting, assembly, and finishing.

- Laser cutting applications – precise high-pressure air for superior cutting quality.

- PET bottle industry – Specialized compressors for PET with 500 HP capacity.

Why Choose Loitha Compressors?

As one of the trusted screw air compressor manufacturers, Loitha offers:

- Wide Range of Air Compressors – From reciprocating air compressors to high-pressure compressors.

- Dependable Air Supply – Our compressor ensures consistent pressure for larger industrial and continuous industrial operations.

- Reduced Energy Consumption – Smart design leads to long-term savings.

- Reliable Performance – Built for heavy-duty industrial applications.

- Integration of Compressor Systems – Simplified installation with air dryer, air tank, and filters included.

Loitha’s High Pressure Screw Air Compressor is engineered to deliver unmatched reliability, cost efficiency, and clean compressed air with minimal maintenance.

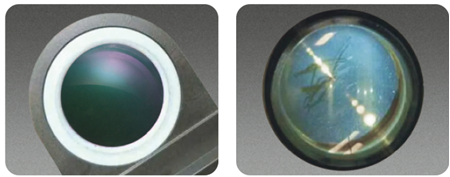

AIR REQUIREMENT OF LASER CUTTING

| Quality of compressed air in laser machine | Air Pressure | > Mpa | 1.0 |

| Cutting Thickness | < 4mm | Carbon steel, Galvanized Sheet, Stainless steel | |

| Solid Particles | < 0.1µm | Class 1 | |

| Pressure Dew Point | < 7° C | Class 5 | |

| Oil and Gas | < 0.1 mg/m3 | Class 1 |

COMPRESSED AIR STANDARD ISO 8573-1 CLASS 0

| Quality Class | Solid Particles | Water | Oil and Gas | |

| µm | Dew Point (°C) | Dew Point (°F) | mg/M3 | |

| 0 | Prescribed by user and suppliers, and more strict than level 1. | |||

| 1 | 0.1 | -70°C | -94°F | 0.01 |

| 2 | 1 | -40°C | -40°F | 0.1 |

| 3 | 5 | -20°C | -4°F | 1 |

| 4 | 15 | 3°C | 37°F | 5 |

| 5 | 40 | 7°C | 45°F | 25 |

| 6 | – | 10°C | 50°F | – |

Advantages

INTEGRATION EASIER INSTALL

- Air compressor, air drier, air tank and line filters integration.

- Avoid the trouble to connect the pipes, can use it after power on.

AIR SUPPLY WITHOUT OIL AND WATER

- The high-efficiency plate-type refrigerated dryer and 4 level high efficiency precision filter to ensure the access to pure compressed air, and the pressure dew point is as low as 2-8°C.

- The post-treatment adopts stainless steel pipelines to avoid sec ondary pollution.

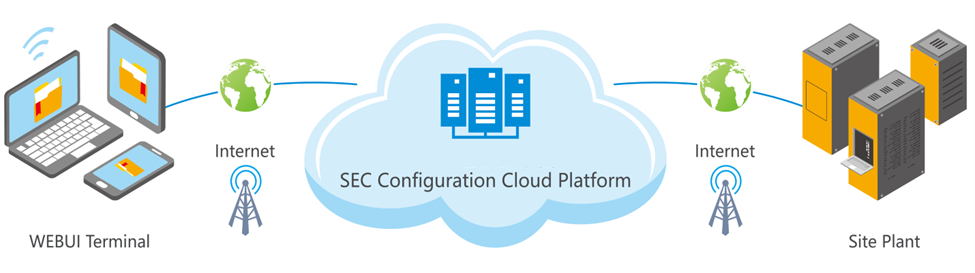

INTELLIGENT MONITORING

- Smart housekeeper remote monitoring, 24-hour online monitoring, no need for special management to open the phone to quickly ob tain machine operation information. When the machine encounters a malfunction or needs maintenance, the system will automatically send an early warning message.

HIGH QUALITY SPARE PARTS

HIGH-END AIR END

- Double screws air end adopts the latest adopts the latest line design and high precision processing technol ogy to reduce internal leak age of compressed air, It will reduce power consumption, and save use costs for cus tomers.

IMPORTED ELECTRONIC ACCESSORIES

- Imported electronic compo nents, high protection and safety level, to ensure the stable operation of the equip ment, and the electrical part is enlarged by 30~50%.

HIGH EFFICIENCY PRECISION FILTER

- Using high-precision and high-pressure-resistant filters, multiple filtrations to ensure that the air supply is oil-free and water-free, production.

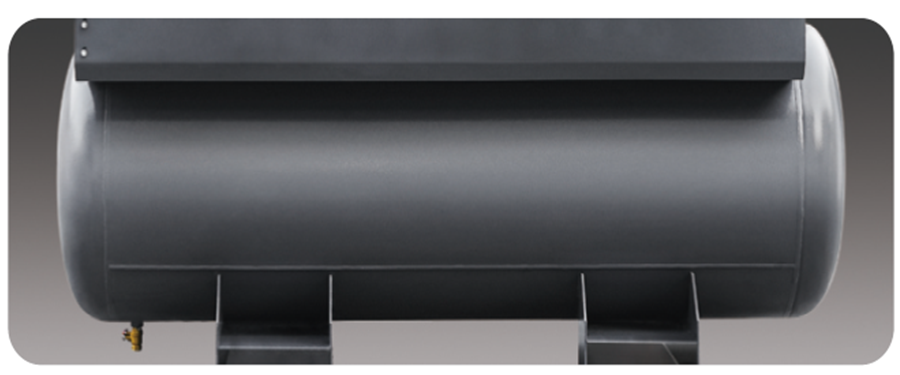

LARGE CAPACITY AIR TANK

- Imported electronic components, high protection and safety level, to ensure the stable operation of the equipment, and the electrical part is enlarged by 30~50%.

Other Specifications

Air Demand Optimization

Intelligent control systems balance fluctuating industrial air demand.

Compressor Life

High-end design ensures extended life cycle for compressors that operate in tough industrial environments.

Energy Efficiency

Loitha compressors provide compressed air solutions that maximize savings.

Pressure Levels

Flexible models to meet pounds per square inch gauge (PSIG) requirements across industries.

Technical Parameter

TECHNICAL PARAMETER OF HIGH PRESSURE SCREW AIR COMPRESSOR

| PARAMETERS LOITHA 4IN 1 TYPE PM VSD LASER MACHINE SCREW AIR COMPRESSOR | |||||||||

| Model | Motor Power | Working Pressure | Free Air Flow | Outer Diameter | Weight | Dimensions | |||

| L x W x H | |||||||||

| 50Hz | kW | Hp | Bar g | Psi g | M3/min | cfm | DN | kg | mm |

| BPM-20A | 15 | 20 | 16 | 232 | 1.25 | 44 | 3/4″ | 540 | 1785 X 840 X 1800 |

| BPM-30A | 22 | 30 | 16 | 232 | 1.8 | 65 | 3/4″ | 600 | 1785 X 840 X 1800 |

| PARAMETERS LOITHA SCREW AIR COMPRESSOR SPECIALLY FOR LASER MACHINE | |||||||||

| Model | Motor Power | Working Pressure | Free Air Flow | Outer Diameter | Weight | Dimensions | |||

| L x W x H | |||||||||

| 50Hz | kW | Hp | Bar g | Psi g | M3/min | cfm | DN | kg | mm |

| AHB-10A | 7.5 | 10 | 16 | 232 | 0.48 | 17 | 1/2″ | 210 | 860 X 730 X 960 |

| AHB-15A | 11 | 15 | 16 | 232 | 0.65 | 23 | 3/4″ | 260 | 940 X 800 X 1075 |

| AHB-20A | 15 | 20 | 16 | 232 | 1.20 | 42 | 3/4″ | 305 | 940 X 800 X 1075 |

| AHB-30A | 22 | 30 | 16 | 232 | 1.75 | 62 | 1″ | 410 | 1200 X 950 X 1150 |

| AHB-50A | 37 | 50 | 16 | 232 | 3.00 | 106 | 1 1/2″ | 610 | 1500 X 990 X 1420 |

| AHB-60A | 45 | 60 | 16 | 232 | 4.30 | 152 | 1 1/2″ | 680 | 1500 X 990 X 1420 |

| AHD-75A | 55 | 75 | 16 | 232 | 5.00 | 177 | 1 1/2″ | 750 | 1500 X 990*1420 |

| AHD-100A | 75 | 100 | 16 | 232 | 6.40 | 226 | 2″ | 870 | 1800 X 1160 X 1490 |

| AHD-120A | 90 | 120 | 16 | 232 | 8.50 | 300 | 2″ | 900 | 1800 X 1160 X 1490 |

| AHD-150A | 110 | 150 | 16 | 232 | 10.70 | 378 | 2″ | 1550 | 2100 X 1400 X 1780 |

| AHD-175A | 132 | 175 | 16 | 232 | 14.50 | 512 | 2 1/2″ | 2050 | 2500 X 1450 X 1800 |

| AHD-220A | 160 | 220 | 16 | 232 | 18.20 | 643 | 2 1/2″ | 2550 | 2500 X 1450 X 1800 |

| Compression stage: High pressure Screw Air Compressor | |||||||||

| Ambient temperature: -5–+45℃ | |||||||||

| Cooling model: Air –Cooling | |||||||||

| Discharg temperature(℃): Ambient temperature+15℃ | |||||||||

| Drive method: Multivee belt drive | |||||||||

| Electricity(V/ph/Hz): 380/3/50 | |||||||||

| Starting method: Direct start / Star-delta starting | |||||||||

TECHNICAL PARAMETER OF HIGH PRESSURE PISTON AIR COMPRESSOR

| Model | Motor Power | Working Pressure | Free Air Flow | Weight | Dimensions | |||

| L x W x H | ||||||||

| 50Hz | kW | Hp | Bar g | Psi g | M3/min | cfm | kg | mm |

| AWH-1030 | 11 | 15 | 30 | 435 | 1.00 | 35 | 450 | 1600 X 850 X 1250 |

| AWH-1230 | 15 | 20 | 30 | 435 | 1.2 | 42 | 460 | 1600 X 850 X 1240 |

| AWH-1630 | 18.5 | 25 | 30 | 435 | 1.6 | 57 | 510 | 1610 X 950 X 1230 |

| AWH-2030 | 22 | 30 | 30 | 435 | 2.0 | 71 | 650 | 1600 X 850 X 1250 |

| 2*AWH-1230 | 30 | 40 | 30 | 435 | 2.4 | 85 | 1000 | 1800 X 1750 X 1250 |

| 2*AWH-1630 | 37 | 50 | 30 | 435 | 3.2 | 113 | 1100 | 1900 X 1900 X 1150 |

| 2*AWH-2030 | 44 | 60 | 30 | 435 | 4.0 | 141 | 1500 | 2000 X 1000 X 2100 |

| 3*AWH-2030 | 66 | 80 | 30 | 435 | 6.0 | 212 | 2300 | 3600 X 1000 X 1800 |

| AWH-1040 | 15 | 20 | 40 | 580 | 1.0 | 35 | 680 | 1600 X 900 X 1250 |

| AWH-2040 | 22 | 30 | 40 | 580 | 2.0 | 71 | 780 | 1800 X 950 X 1360 |

| 2*AWH-1540 | 37 | 50 | 40 | 580 | 3.0 | 106 | 1500 | 2400 X 1000 X 1800 |

| 2*AWH-4040 | 44 | 60 | 40 | 580 | 4.0 | 141 | 1560 | 2400 X 1000 X 1800 |

| 3*AWH-6040 | 66 | 80 | 40 | 580 | 6.0 | 212 | 2100 | 3600 X 1000 X 1800 |

| 4*AWH-8040 | 88 | 120 | 40 | 580 | 8.0 | 283 | 3150 | 4800 X 1000 X 1800 |

| Compression stage: High pressure piston compressor | ||||||||

| Ambient temperature: -5–+45℃ | ||||||||

| Cooling model: Air –Cooling | ||||||||

| Discharg temperature(℃): Ambient temperature+15℃ | ||||||||

| Drive method: Multivee belt drive | ||||||||

| Electricity(V/ph/Hz): 380/3/50 | ||||||||

| Starting method: Direct start / Star-delta starting | ||||||||

Conclusion

The High Pressure Screw Air Compressor by Loitha is not just a machine — it’s a long-term investment in compressed air solutions. Built for industrial processes, engineered for reliable performance, and designed to meet strict air quality standards, it is the ideal choice for industries needing consistent pressure, higher output, and clean compressed air.

Whether you require a stage screw air compressor, rotary screw air compressor, or variable-speed high pressure air compressors, Loitha offers a wide range of air compressors tailored to your needs. Our compressors are designed to deliver dependable, energy-efficient compressed air for every industrial operation.